Slab Gate Valves

Slab Gate Valves

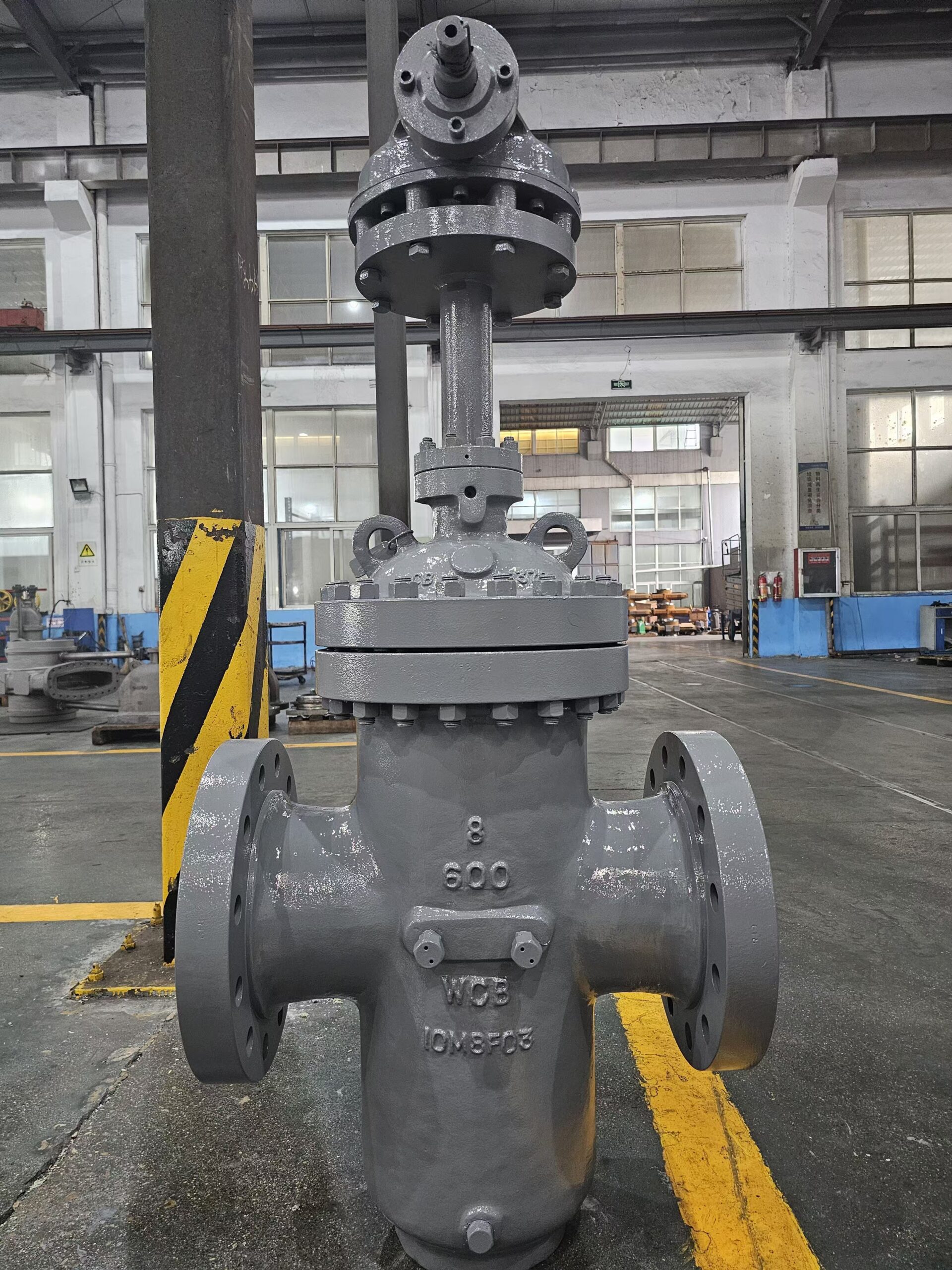

Through Conduit Slab Gate Valves

Laminar Slab Gate Valves, also known as “Through Conduit Gate Valves,” are produced and tested in compliance with the API-6D standard. This type of valve is highly effective in transportation pipelines for gas, crude oil, and oil products. The Slab Gate Valve features a through conduit design and is piggable. It is engineered to minimize pressure drop and capture foreign particles, such as slurries, in the disc cavity, helping to maintain the cleanliness of the sealing surfaces.

FULL OPENING THROUGH CONDUIT DESIGN: LAMINAR

The Slab Gate Valve features a full-opening through conduit design that enables pipeline fluids to flow smoothly with minimal turbulence. In the open position, it allows pigs, scraper wipers, or hot tap cutters to pass through the pipeline without risk of damaging the internal components. Its full-flow design prevents line scrapers from getting lodged in the valve bore and stops metal debris from jamming the moving parts. The bore is circular, as specified in API-6D table 1.

ENERGIZED SEAT FOR POSITIVE SEALING

When the slab-type disc is in the closed position, the valve seats (one on each side of the gate) are energized to ensure tight sealing both upstream and downstream. The seats have a circular nylon or RPTFE (Reinforced PolyTetraFluoroethylene) insert on the sealing faces. Two elastomer O-rings on the peripheral surfaces of the seats prevent fluid from passing through the seats when the valve expands under pressure. This way, the sealing effectiveness of the O-rings actually increases as the fluid pressure rises.

TIGHT SEALING

The LAMINAR Slab Gate Valve uses the resultant force from line pressure to create a tight mechanical seal on the downstream side under high differential pressure. Low-pressure sealing is achieved by internal springs, which push the seats against the disc to ensure an effective seal.

MAINTENANCE

Slab Gate Valves are designed to be maintenance-free. The Chevron-Viton packing on the valve stem can be repacked while the valve remains under pressure in the open position. Additionally, trained service personnel or the manufacturer can perform a complete overhaul of the valve.

NO LUBRICATION NEEDED

Under normal operating conditions, the Slab Gate Valve does not require lubrication for sealing. In case of damage to sealing components, a sealant can be injected as a temporary solution until proper repair can be performed.

BACKSEAT

The Slab Gate Valve features a backseat bushing that isolates the packing chamber from the pressure line, allowing for packing replacement. A secondary seal is also incorporated inside the packing chamber.

EMERGENCY SEALANT INJECTOR SYSTEM ON SEAT RINGS

In the event of seat ring damage during service, a secondary plastic sealant injection system is available (if specified by the customer) to seal all surfaces of the seat rings. This is a temporary solution to maintain valve sealing until repairs can be made. These sealing fittings are positioned strategically to ensure full coverage of the sealing surfaces, enabling a complete seal around the seats.

SEAT ARRANGEMENT

The seat arrangement comprises ENP-coated seats and soft inserts to ensure that primary sealing occurs at the gate. If the soft seat becomes damaged, the metal-to-metal seating will function as a secondary seal. A metal-to-metal seating design is also available for abrasive applications upon request.

DOUBLE BLOCK & BLEED DESIGN (DBB)

The Slab Gate Valve can undergo maintenance or repair in-line without being removed from the pipeline. When pressure is present on both sides of the valve (upstream and downstream), the seat ring design activates to press against the disc and maintain the valve seal. Once the valve is acting as “DBB,” any pressure or fluid in the body-bonnet cavity can be released through the body drain system.

To test this feature with the valve partially open, the valve and its cavity should be completely filled with test fluid. Then the valve must be closed, and the valve body vent valve opened to allow excess test fluid to overflow from the test connection. Test pressure should be applied simultaneously from both ends of the valve, with seat tightness monitored through the valve cavity connection.

UNIDIRECTIONAL SEATS

LAMINAR Slab Gate Valves are unidirectional, meaning they are designed to self-relieve pressure from both the downstream and upstream directions.

To test this feature with the valve partially open, the valve and its cavity should be completely filled with test fluid. The valve must then be closed, and test pressure applied to the central cavity. Overpressure will be relieved through both ends of the valve.

Specifications

PRESSURE RATING | Class 150 to Class 2500 |

DN | 2 inches to 72 inches |

Medium | Crude oil, natural gas, refined products, chemicals, water, steam, and slurries. Suitable for high-pressure, corrosive, and abrasive mediums. |

Application | For critical isolation and flow control in oil & gas pipelines, petrochemical plants, LNG/LPG systems, and power plants. |

Specifications | Technical Specification

Product Range

Design Features

|